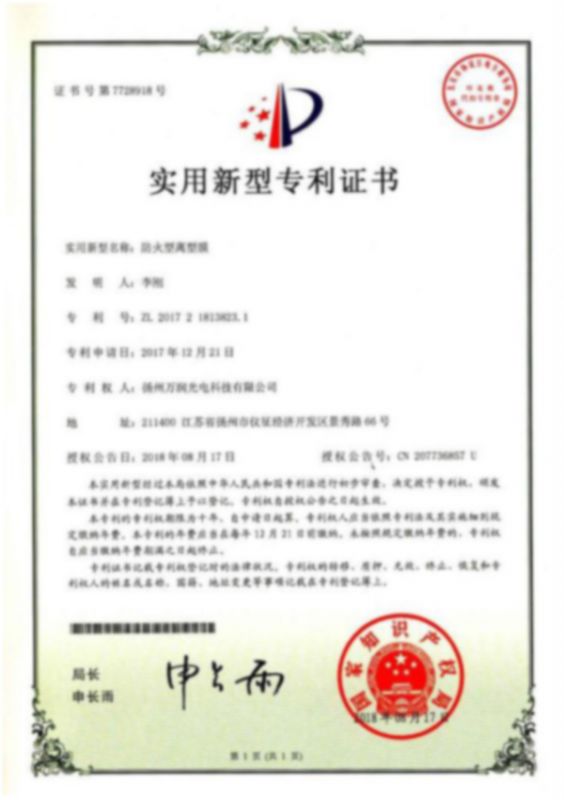

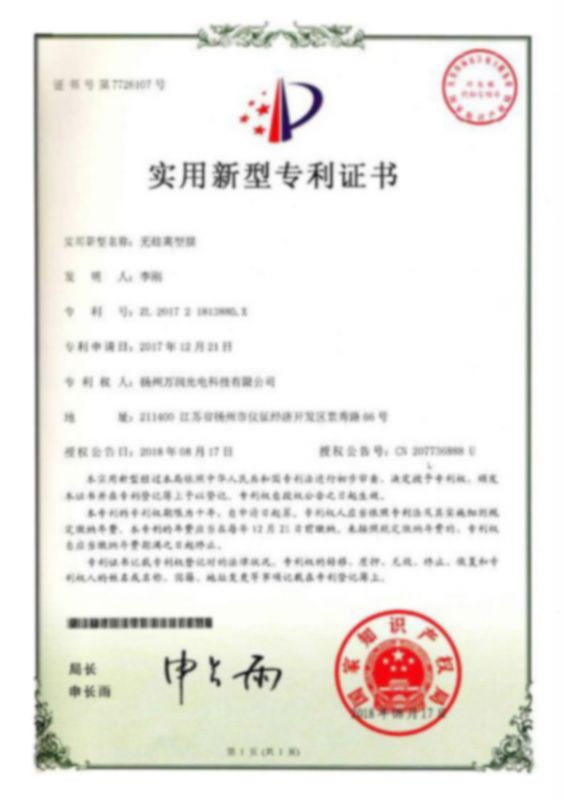

Our company attaches great importance to the investment in R&D, and currently has 12 invention patents and 25 utility model patents.

Tel:+86-0514-80857098

Fax:

Mail:jmx@yzalvin.com

Linkman:

Add:No. 66, Jingxiu Road, Yizheng Economic Development Zone, Jiangsu Province (in Lipu Industrial Park)

联网备案号:

联网备案号: